The LARTE Design team of professionals has extensively researched the best materials for auto body kits. We tested fiberglass, polyurethane, ABS plastic, carbon fiber, and composite materials to help you choose the best option for your needs.

The LARTE Design team of professionals has extensively researched the best materials for auto body kits. We tested fiberglass, polyurethane, ABS plastic, carbon fiber, and composite materials to help you choose the best option for your needs.

BACK

How to Choose the Best Material For a Car Body Kit

Understanding Car Body Kits

TYPES OF CAR BODY KITS

-

Lip Kits: These are the simplest form of body kits, consisting mainly of front and rear lips or splitters that complement to the existing bumpers. They provide a subtle enhancement without drastically changing the car’s look.

-

Wide-Body Kits: These kits include larger fenders and often require significant modifications to the car’s structure. They allow for wider tires, which can improve traction and handling. Side Skirts are also often included to complete the look.

-

Full-Body Kits: As the name suggests, these kits cover the entire car, replacing or adding to the Bumpers, Side Skirts, and sometimes even the hood and trunk. Full-Body Kits offer the most dramatic transformation.

WHY MATERIAL MATTERS IN CAR BODY KITS

-

Durability: Different materials offer varying levels of resistance to impact, weather, and wear and tear. For example, fiberglass is lightweight and easy to mold, but it can crack more easily compared to polyurethane or carbon fiber.

-

Performance: The weight of the material can impact your vehicle's performance. Lighter materials like carbon fiber can reduce the overall weight of the car, improving speed and fuel efficiency. However, lighter materials may also be more expensive.

-

Cost: The material you choose will significantly affect the price of the body kit. Fiberglass is often more affordable, while carbon fiber, known for its strength and lightness, can be much more expensive.

-

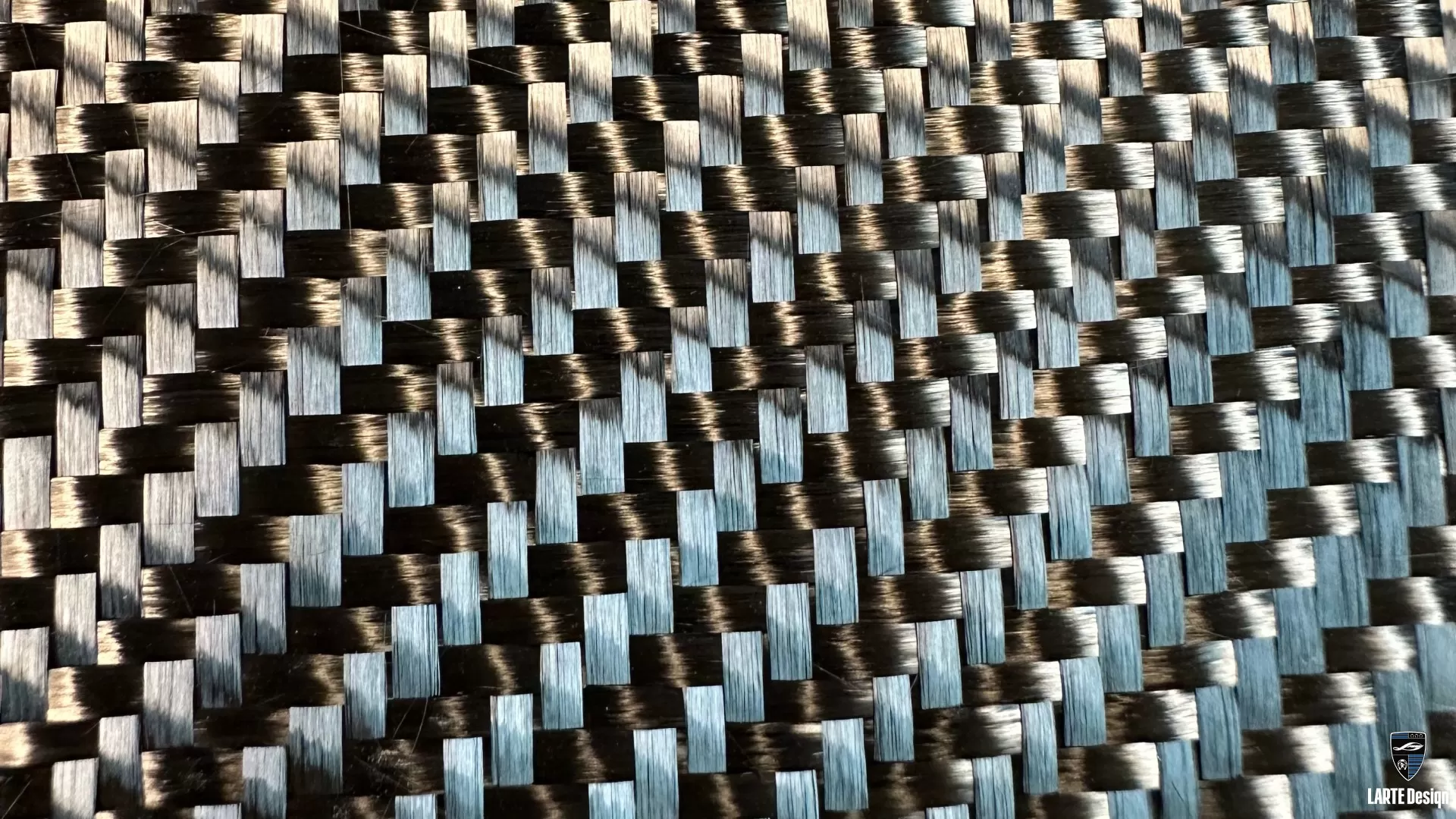

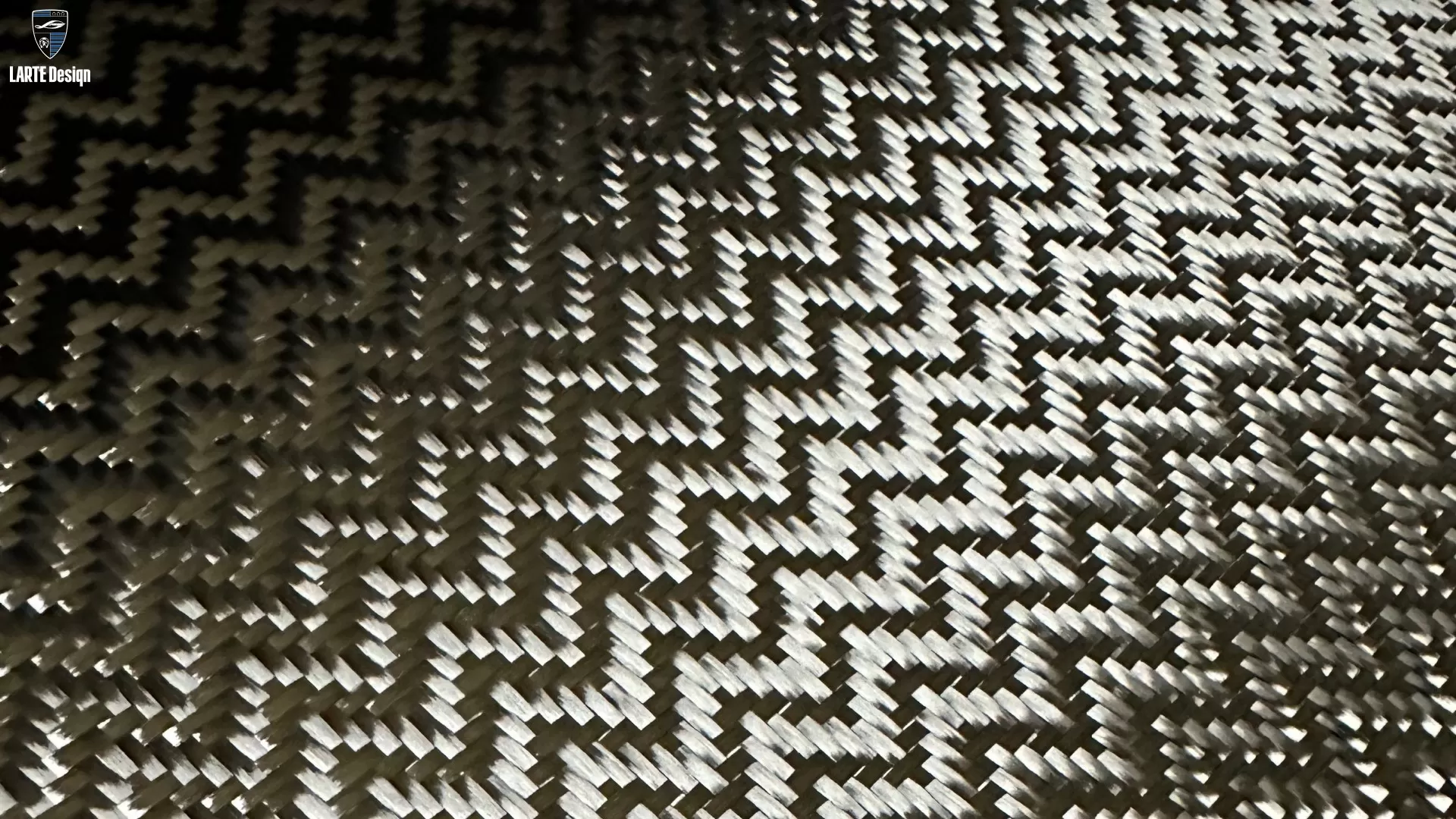

Aesthetics: Each material offers a different finish and texture. Polyurethane or urethane can be painted to match your car's body color. Carbon fiber has a distinctive woven pattern that is highly sought after for a high-performance, premium look.

Popular Materials for Car Body Kits

| Material | Durability | Weight | Cost | Ease Of Installation |

|---|---|---|---|---|

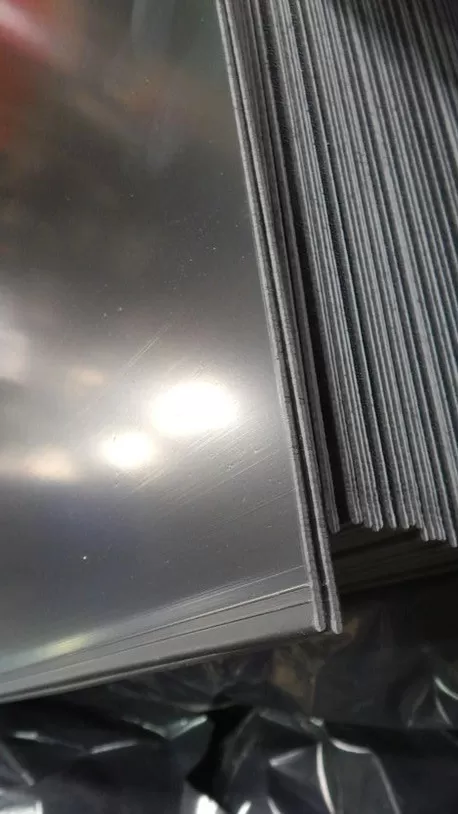

| Carbon Fiber | High strength, highly durable, but can be brittle | Ultra-lightweight | Very high | Requires precision, challenging for DIY installations |

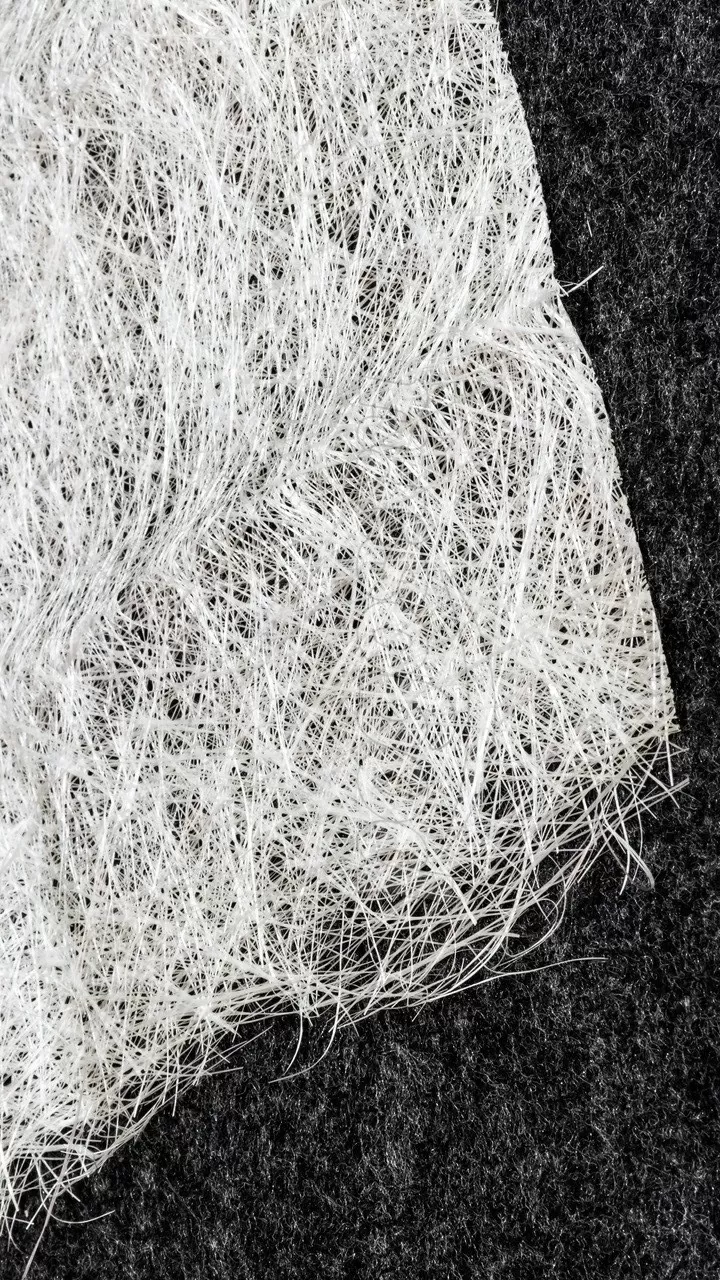

| Fiberglass | Durable but prone to cracking; requires finishing | Lightweight | Cost-effective | Easy to mold and install, requires post-installation work |

| ABS Plastic | Good impact resistance, flexible | Heavier than fiberglass | Moderately priced | Straightforward installation, less finishing work |

| Composite | Balanced strength and durability, varies by blend | Heavier than carbon fiber, lighter than others | Mid-range | Generally easier to install than carbon fiber |

| Polyurethane | Highly durable, flexible, and resistant to impacts | Heavier than others | Higher than fiberglass but less than carbon fiber | More forgiving during installation, better fit and finish |

Factors to Consider When Choosing Body Kit Materials

Comparing Body Kit Materials

Maintenance and Care

Fiberglass

-

Cleaning: Fiberglass body kits should be cleaned regularly with mild car shampoo and a soft cloth to avoid scratches. Harsh chemicals or abrasive cleaners can damage the resin, so it’s best to stick with products specifically designed for automotive use.

-

Polishing: To maintain the shine and protect the surface from UV damage, use a high-quality car wax or polish. This also helps to fill in any minor scratches, keeping the fiberglass looking smooth and glossy.

-

Protection: Applying a protective sealant or clear coat can prevent moisture from penetrating the surface, reducing the risk of cracks and delamination. This is especially important in areas with harsh weather conditions.

Polyurethane

-

Cleaning: Polyurethane is durable and flexible but should still be cleaned with care. Use a gentle soap and water solution, avoiding harsh chemicals that could degrade the material over time. A microfiber cloth is ideal to prevent scratching.

-

Polishing: Regular polishing with a suitable wax can enhance the finish of painted polyurethane body kits, helping to protect the color from fading due to UV exposure.

-

Protection: To prevent cracking and prolong the life of the material, apply a UV-protective coating, especially if the body kit is exposed to a lot of sunlight.

ABS Plastic

-

Cleaning: ABS plastic is relatively easy to maintain. Clean it with standard car wash products, using a microfiber cloth to avoid scratching. Be cautious with strong solvents, as they can cause the plastic to become brittle over time.

-

Polishing: While not always necessary, you can use a plastic-specific polish to restore the shine and remove any superficial scratches. This helps maintain the overall aesthetic of the body kit.

-

Protection: Applying a UV-protective coating can prevent discoloration and warping, especially in regions with strong sunlight.

Composite Materials

-

Cleaning: Composite materials, which blend the strengths of different materials, should be cleaned with mild car shampoo and a soft cloth. Avoid using harsh chemicals that could degrade the material's integrity.

-

Polishing: Depending on the surface finish, composite materials can benefit from regular polishing with a car wax or specialized polish. This helps protect the surface and maintain its appearance.

-

Protection: Composite materials often come with a protective coating, but it’s a good idea to reapply a protective layer periodically, especially if the kit is exposed to harsh environmental conditions.

Carbon Fiber

-

Cleaning: Carbon fiber requires specialized care due to its unique properties. Use car care products specifically designed for carbon fiber, and avoid abrasive cloths or sponges that could damage the surface.

-

Polishing: To maintain the distinct weave pattern and protect the resin from UV rays, use a high-quality carbon fiber polish. This helps to keep the material looking new and enhances its durability.

-

Protection: Applying a ceramic coating is highly recommended for carbon fiber, as it offers superior protection against environmental damage and keeps the material in pristine condition for longer.

REPAIR CONSIDERATIONS

Fiberglass

-

Repair Ease: Fiberglass is an easy materials to repair. Small cracks, chips, or holes can be patched using fiberglass repair kits, which are widely available and relatively easy to use. However, repairs may require sanding, painting, and polishing.

-

Considerations: While repairs are straightforward, they might not always be seamless. Proper finishing work is needed to achieve a smooth, uniform appearance.

Polyurethane

-

Repair Ease: Polyurethane’s flexibility and impact resistance make it less prone to severe damage, but repairs can be challenging due to its rubbery texture. Specialized adhesives or patches are often required to fix tears or cracks.

-

Considerations: Polyurethane repairs tend to be more involved and may require professional help to ensure the repair matches the original material’s durability and appearance.

ABS Plastic

-

Repair Ease: ABS plastic can be tricky to repair due to its rigid structure. Heat welding or using plastic-specific adhesives is often necessary to repair cracks or breaks effectively. The process can be complex and may require specialized tools.

-

Considerations: While durable, ABS plastic repairs need to be precise to maintain the integrity of the material. Professional assistance might be required for larger or more complex repairs.

Composite Materials

-

Repair Ease: The reparability of composite materials depends on their specific blend. While some composites can be repaired similarly to fiberglass, others may require specialized techniques and materials, making repairs more complex and costly.

-

Considerations: Due to the variability in composite materials, repairs should be approached with caution, and professional evaluation might be necessary to ensure a proper fix.

Carbon Fiber

-

Repair Ease: Carbon fiber is the most challenging material to repair. Due to its complex weave and resin structure, repairing cracks or damage often requires specialized equipment and expertise. Repairs can be expensive and time-consuming.

-

Considerations: Given the difficulty of repairing carbon fiber, it's often more practical to replace damaged components rather than attempt repairs. However, for minor cosmetic damage, a skilled technician may be able to perform a successful repair.

Making the Final Decision

Frequently Asked Questions

OTHER ARTICLES

Prepreg vs vacuum infusion: complete comparison guide

This guide explains how prepreg vs vacuum infusion impacts structural consistency, durability, and long-term performance.

Manufacture

Design

BMW X7 60i meets LARTE DESIGN: a transformation that turns heads

The story of Gytis from Lithuania, a real estate agent, owner of a BMW X7 60i redesigned by our studio.

BMW

Design

LARTE Design - LA Autoshow

LARTE Design presented spectacular tuning projects at the autotuning exhibition in Los Angeles

Awards